G-Code and M-Code are the languages used to program CNC machines. They are a set of codes and commands that tell the machine what to do, including the cutting tool’s position, the speed, and the feed rate.

- G-Code: G-Code is the most widely used code in CNC programming. It is responsible for controlling the movement of the cutting tool and determining the final shape of the part. G-Code commands include G00 (rapid positioning), G01 (linear interpolation), and G02 (circular interpolation).

- M-Code: M-Code, also known as miscellaneous codes, are used to control various functions of the CNC machine, such as the coolant, tool changes, and program stops. M-Code commands include M00 (program stop), M01 (optional program stop), and M02 (end of program).

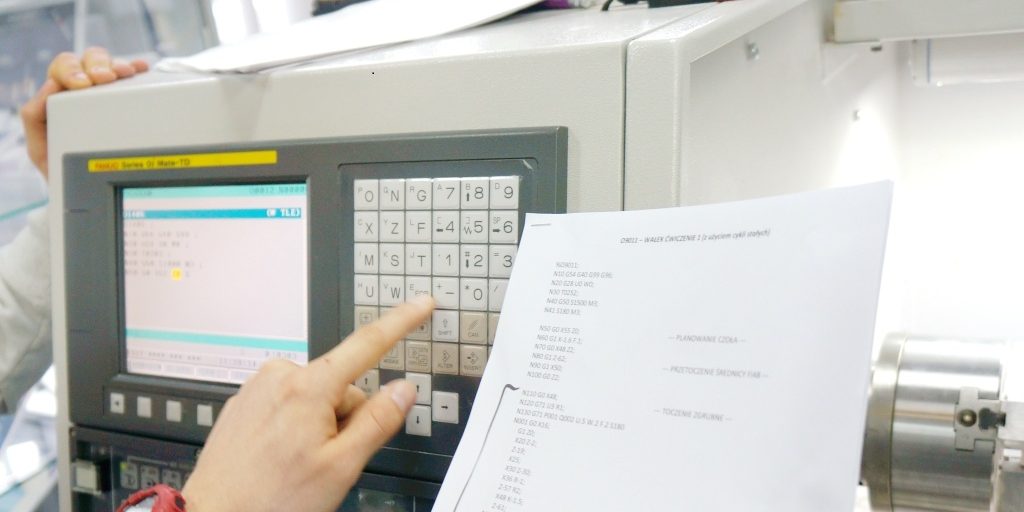

- CNC Programming: CNC programming involves writing a series of G-Code and M-Code commands that tell the CNC machine what to do. These commands are organized into a program that is then loaded into the machine’s controller.

CNC programming can be done manually or using computer-aided manufacturing (CAM) software. CAM software simplifies the programming process by automatically generating the G-Code and M-Code commands based on a 3D model of the part.

- Advantages of CNC Programming: CNC programming offers several advantages over manual machining, including increased accuracy and repeatability, faster production times, and reduced human error. With CNC programming, a single operator can control multiple machines, reducing the need for multiple machinists.

To Summarise, G-Code and M-Code are the fundamental languages of CNC programming. Understanding these codes is essential for effectively programming CNC machines and producing high-quality parts with precision and efficiency.